Austenitic Stainless Steel Pipe

Introduction of Austenitic Stainless Steel Pipe:

A stable austenite structured steel contains about 18% Cr, 8% ~ 10% Ni and about 0.1% C. Chrome-nickel austenitic stainless steel including the most familiar stainless steel 18Cr-8Ni (TP304) and the series of high Cr-Ni steel developed by increase Cr, Ni contents and add Mo, Cu, Si, Nb, Ti and other elements. Austenitic stainless steel is characterized by non-magnetic, high plasticity and ductility but lower strength. It can be only strengthened via cold working (by adding S, Ca, Se, Te and etc, austenitic stainless steel can have excellent machinability). Austenitic steels are non-magnetic stainless steels that contain high levels of chromium and nickel and low levels of carbon. Known for their formability and resistance to corrosion, austenitic steels are the most widely used grade of stainless steel.

About Austenitic Stainless Steel:

Austenitic stainless steels are classified in the 200 and 300 series,with 16% to 30% chromium and 2% to 20% nickel for enhanced surface quality formability,increased corrosion and wear resistance.The austenitic stainless steels are more easily recognized because of their non magnetic properties.Depending on the compositionsome austenitics do become somewhat magnetic when cold worked.While austenitic steels are more expensive than ferritic stainless steel Austenitic stainless steels are non-hardenable by heat treating

What is 200 and 300 series Austenitic Stainless Steel Tubes?

200 Series Stainless Steels

Stainless steels with a low nickel and high nitrogen content are classified as 200 series.These are chromium-nickel-manganese austenitic stainless steels.Grade 201 is hardenable through cold working while the grade 202 is a general purpose stainless steel. Decreasing nickel content and increasing manganese results in weak corrosion resistance.

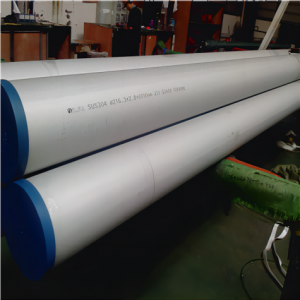

300Series Stainless Steels

The most common austenitic stainless steels are iron-chromium-nickel steels and are widely known as the 300 series. In this series the most widely used austenitic stainless steel is the grade 304.also known as 18/8 for its composition of 18% chromium and 8 % nickel.The second most common austenitic stainless steel in this series is the grade 316,also called marine grade stainless steelused primarily for its increased resistance to corrosion. A typical composition of18%chromium and 10%nickelcommonly known as 18/10 stainless, is often used in cutlery and high quality cookware.

Features of Austenitic Stainless Steel Tubes

Corrosion Resistance

Corrosion resistance in stainless steels is primarily determined by chromium content. Austenitic stainless steels as a class have excelentcorrosion resistance and those with molyodenum additons hae improved piting resistance The nicke! content in austenitic stainless steeishelps to reduce the rate of corrosion,particularly in acid enyironments. Austenitic grades, however are susceptible to chloride stress corrosioncracking (SCC) and are not recommended for service that combines tensile stress and the presence of chlorides, even at moderatecemperatures,Higher carbon austenitic grades can be susceptible to intergranular corosion ater certain high temperature exposuresncluding welding,For appications that require welding, a post-weld heat treatment or selection of a low carbon or stabilized grade such aslpe 304L 316L and 321, is recommended

Formability

Austenitic stainless steels are generally considered to have excelent formability. lean austenitic grades including NITRONIC 30,Type 201 andlype 301, have high work hardening rates and resistance to thinning which results in improved stretch formability. For deep drawing it isgenerally advised to use higher nickel content, lower work hardening grades such as Types 304 or 305.

Weldability

Austenitc stain ess steis exhiit similar we ding characterstics These a ovs can be oined by shie ded fuson and resistance we dingprocesses. Cood mechanical strength is developed in welded joints without the necessity of preheating or post-weld annealing. Heattreatment or alternative selection of a low-carbon grade is advised to prevent corrosion in the weld area. The physical properties of austeniticstainless steels must be taken into consideration when developing appropriate welding practices

Temperature

im service conditions with extreme temperatures either cryogenic or elevated. austenitic stainless steeis are we. suited. Some austeniticgrades retain good ductlity and impact strength at sub-zero temperatures. These alloys also maintain tensile and creep strength at elevatedtemperatures.

Chemical Composition of Austenitic Steels:

| AlSl grade | C max. | Si max. | Mn max. | Cr | Ni | Mo | Ti | Nb | Al | v |

| 301 | 0.15 | 1.00 | 2.00 | 16-18 | 6-8 | |||||

| 302 | 0.15 | 1.00 | 2.00 | 17-19 | 8-10 | |||||

| 304 | 0.08 | 1.00 | 2.00 | 17.5-20 | 8-10.5 | |||||

| 310 | 0.25 | 1.50 | 2.00 | 24-26 | 19-22 | |||||

| 316 | 0.08 | 1.00 | 2.00 | 16-18 | 10-14 | 2.0-3.0 | ||||

| 321 | 0.08 | 1.00 | 2.00 | 17-19 | 9-12 | 5x%C min. | ||||

| 347 | 0.08 | 1.00 | 2.00 | 17-19 | 9-13 | 10 x%C min. | ||||

| E 1250 | 0.1 | 0.5 | 6.0 | 15.0 | 10.0 | 0.25 | ||||

| 20/25-Nb | 0.05 | 1.0 | 1.0 | 20.0 | 25.0 | 0.7 | ||||

| A 286 | 0.05 | 1.0 | 1.0 | 15.0 | 26.0 | 1.2 | ~1.9 | ~0.18 | ~0.25 | |

| 254SMO | 0.02 | 0.8 | 1.0 | 18.5-20.5 | 17.5-18.5 | 6-6.5 | ~1.9 | ~0.18 | ~0.25 | |

| AL-6XN | 0.03 | 1.0 | 2.0 | 20-22 | 23.5-25.5 | 6-7 |

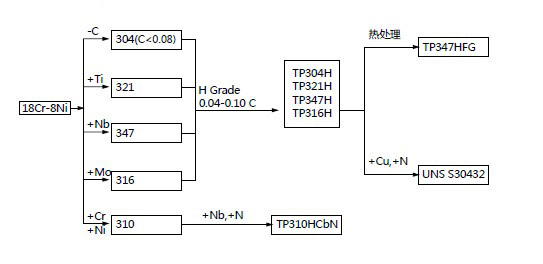

Development diagram of common grades of austenitic stainless steel:

Austenitic grades of stainless steels are the most commonly used grades, mainly because they provide very predictable level of corrosion resistance with excellent mechanical properties. Using them wisely can save the designer of a product significant cost. These steels are user friendly metal alloy with life cycle cost of fully manufactured products lower than many other materials. Austenitic stainless steels are those steels which are commonly used for stainless application. Some of the applications for austenitic stainless steel include the following. •Kitchen sinks •Architectural applications such as roofing and cladding •nterior decoration •Roofing and gutters •Doors and windows •Kitchenware,cutlery and cookware •Benches and food preparation areas •Food processing equipment •Heat exchangers •Ovens and furnace parts •Chemical tanks