Duplex Stainless Steel Pipe

Introduction of Duplex Stainless Steel Pipe:

Duplex stainless steel is a very useful metal that is used the world over. It gets its name from the fact that it consists of two different grades of metal.

Essentially, Duplex is a Fe-Ni-Cr alloy that has a two-phase ferritic-austenitic stainless-steel microstructure when it is at room temperature.

Duplex steels are characterised by high chromium (19–28%) and molybdenum (up to 5%) and lower nickel contents than austenitic stainless steels. The most used duplex stainless steels are the 2205 (22% Chromium, 5% Nickel) and the 2507 (25% Chromium, 7% Nickel); 2507 is known as “super duplex” due to its higher resistance to corrosion.

The advantage of combining ferritic and austenitic grades is that the resultant metal has a metallurgical structure that consists of two phases and therefore benefits from the properties of both microstructures.

These properties make duplex steel highly sought after in heavy industries, like oil and gas nuclear and chemical processing.

CHEMICAL COMPOSITION (%):

| Grades | C≤ | Mn≤ | Si≤ | S≤ | P≤ | Cr | Ni | Mo | Cu≤ | N |

| S32750((SAF2507) | 0.03 | 1.2 | 0.8 | 0.02 | 0.035 | 24.0/ | 6.0/ | 3.0/ | 0.5 | 0.24/ |

| 00Cr22Ni7Mo4N | 26 | 8 | 5 | 0.32 | ||||||

| S31803(SAF2205) | 0.03 | 2 | 1 | 0.02 | 0.03 | 21.0/ | 4.50/ | 2.50/ | 0.08/ | |

| 00Cr22Ni5Mo3N | 23 | 6.5 | 3.5 | 0.2 | ||||||

| S31500(3RE60) | 0.03 | 1.2/ | 1. 4/ | 0.03 | 0.03 | 18.0/ | 4.25/ | 2.50/ | 0.05/ | |

| 00Cr18Ni5Mo3Si2 | 2 | 2 | 19 | 5.25 | 2 | 0.1 |

MECHANICAL PROPERTIES:

| Heat treatment temperature/℃ | Ab(MPa)≥ | As(MPa)≥ | ∮≥ | Brudzinski | Rockwell | |

| S32750(SAF2507) | 1025-1125 | 800 | 550 | 15 | 310 | 32 |

| 00Cr22Ni5Mo3N | ||||||

| S31803(SAF2205) | 1020-1100 | 620 | 450 | 25 | 290 | 30.5 |

| 00Cr22Ni5Mo3N | ||||||

| S31500(3RE60) | 980-1040 | 630 | 440 | 30 | 290 | 30.5 |

| 00Cr18Ni5Mo3Si2 |

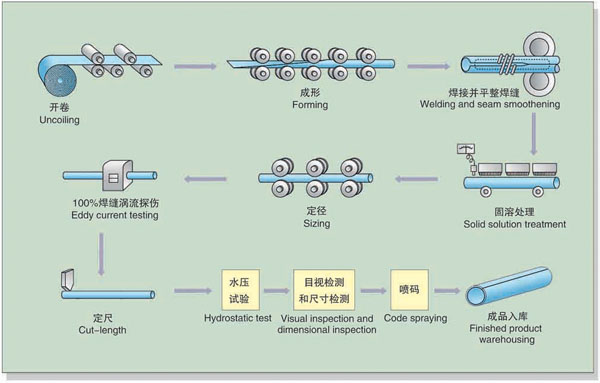

Manufacturing Technique Of Duplex Stainless Steel Pipe

Applications of Duplex Stainless Steel Pipe

The extensive benefits of Duplex stainless steel mean that it can be used in many different applications such as:

•Chemical processing, transport and storage

•Pipes for production and transportation of oil and gas

•Oil and gas exploration and offshore rigs

•Oil and gas refining

•Marine environments

•Pollution control equipment

•Pulp & paper manufacturing

•Chemical process plant

•Structural and mechanical components

•Heat exchangers

•Cooling pipes