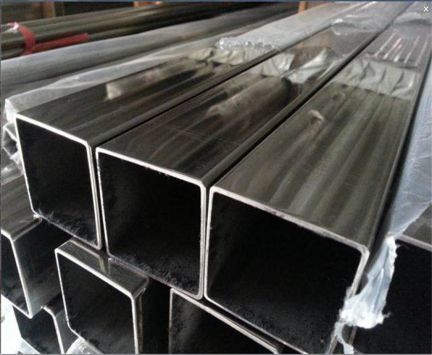

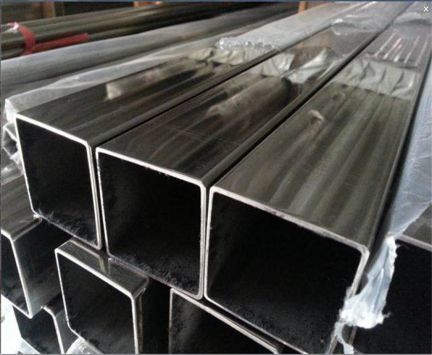

The stainless steel square tube is a hollow, long strip of steel, which is called a square tube because of its square cross-section. A large number of pipelines are used to transport fluids, such as petroleum, natural gas, water, gas, steam, etc. In addition, they are lighter when the bending and torsion strength are the same, so they are also widely used in the manufacture of mechanical parts and engineering structures.

Stainless steel square pipes are divided into two categories: seamless steel pipes and welded steel pipes (seam pipes). According to the cross-sectional shape, it can be divided into square and rectangular pipes. Round steel pipes are widely used, but there are also some special-shaped steel pipes such as semicircle, hexagon, equilateral triangle, octagon and so on.

For stainless steel square pipes subjected to fluid pressure, hydraulic tests must be carried out to verify their pressure resistance and quality. They are qualified without leakage, wetting or expansion under the specified pressure. Some steel pipes are also subject to crimping test, flaring test, flattening test, etc. according to the standard or the buyer's requirements.

Square tube specifications: 5*5~150*150 mm Thickness: 0.4~6.0 mm

Square tube material: 304, 304L, TP304, TP316L, 316, 316L, 316Ti, 321, 347H, 310S.

Causes of rust

Metals can react with oxygen in the atmosphere to form an oxide film on the surface. The iron oxide formed on ordinary carbon steel will continue to oxidize, causing the rust to continue to expand and eventually forming holes. This can use paint or oxidation-resistant metal plating to protect the surface of carbon steel, but this protective layer is just a thin film. If the protective layer is damaged, the steel below will begin to rust again. Whether the stainless steel pipe is corroded is related to the chromium content in the steel. When the chromium content in the steel reaches 12%, in the atmosphere, a layer of passivated and dense chromium-rich oxide is formed on the surface of the stainless steel pipe to protect the surface. Further oxidation. This oxide layer is extremely thin, and the natural luster of the steel surface can be seen through it, giving the stainless steel a unique surface. If the chromium film is destroyed, the chromium in the steel and the oxygen in the atmosphere will regenerate a passivation film to continue to play a protective role. In some special environments, stainless steel will also experience some local corrosion and fail. However, unlike carbon steel, stainless steel will not fail due to uniform corrosion, so the corrosion allowance is meaningless for stainless steel pipes.

In industry, stainless square tubes are mainly used to make some conveying pipes. Of course, it is more widely used in the construction industry. Stainless steel square tubes are used for some shallow-drawn products. Such as shallow processing cookware, indoor staircase handrails, elevators, mirrors, brushed surface and other surface processed products; door and window guardrails, hangers, various brackets for anti-theft windows; supermarket containers, anti-theft door frames, etc.

Hunan Great Steel Pipe Co., Ltd. is a modern comprehensive production enterprise integrating processing, manufacturing and sales of stainless steel coils, stainless steel sheets, stainless steel tubes, cold rolled steel, galvanized steel, galvanized steel and painted steel. We have advanced professional knowledge and technical expertise, which can well meet the strict requirements of our valuable customers. If you are interested in stainless steel square pipes, welcome to inquire!