-

Precautions for storage of galvanized steel pipes and methods for dealing with alkali reversion

First: Causes of anti-alkali (white rust, black spots) 1. The formation principle of white rust: When galvanized products are tightly packed and placed in humid air since there is no free-flowing air on the surface of the product, electrochemical corrosion will occur on the surface of the zinc la...Read more -

Do you know these eight things about seamless steel pipes

(1) The wall thickness coverage of seamless steel pipes is relatively wide and can achieve small diameters and large wall thicknesses and large diameters and large wall thicknesses, but the length is generally limited (only a few manufacturers can produce ultra-long pipes); stainless steel welded...Read more -

Explore the details of the tensile strength of industrial small-diameter seamless steel pipes

The tensile strength (Rm) of small-diameter seamless steel pipe refers to the maximum stress value the material withstands before breaking. When the small-diameter seamless steel pipe yields to a certain extent, its ability to resist deformation increases again due to the rearrangement of the int...Read more -

Construction preparation before welding of large-diameter steel pipes and introduction to inner wall anti-corrosion

Construction preparation before large-diameter steel pipe welding: 1. Organize relevant operators, familiarize themselves with construction drawings and procedures, formulate welding procedures, and compile welding operation instructions. 2. Welders should be trained in corresponding projects and...Read more -

What are the types of heat treatments for stainless steel welded steel pipes

During the production process of stainless steel welded steel pipes, intermediate heat treatment, and finished product heat treatment can be carried out. Because a bright surface without oxidation can be obtained, the traditional pickling process is eliminated. The use of this heat treatment proc...Read more -

Steel elbow process flow

Seamless steel elbow: Steel elbow is a kind of pipe fitting used at the end of the pipeline. Among all the pipe fittings used in the pipeline system, the proportion is about 80%. Usually, different forming processes are selected for steel elbows of different materials or wall thicknesses. Commonl...Read more -

What environments are large-diameter steel pipe suitable for

1. Petrochemical: crude oil, refined oil, petrochemical raw materials, and finished product transportation pipes and oil field pipeline networks. 2. Natural gas: submarine and onshore long-distance pipelines; gas receiving station gas transmission pipelines; gas fields and urban natural gas pipel...Read more -

What are the characteristics of the Cr2 steel pipe heat treatment process

The heat treatment process of the Cr2 steel pipe mainly includes steps such as annealing, normalizing, and quenching. These steps have their unique characteristics and purposes. Annealing is to heat the Cr2 steel pipe to about 800°C, hold it for a certain period, and then slowly cool it. The main...Read more -

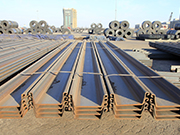

Steel sheet pile construction process

1. Inspection and correction of steel sheet piles Steel sheet piles used for temporary support of foundation pits are inspected for surface defects, length, width, thickness, height, end rectangularity ratio, straightness, and lock shape, and welding parts on the piles that affect the installatio...Read more -

What is the heat treatment of stainless steel pipe fittings

There are many types of heat treatments for stainless steel pipe fittings, including solution treatment, stabilization treatment, stress relief treatment, and weld heat treatment. 1. Solution treatment is to heat stainless steel pipe fittings to the austenite zone to fully dissolve chromium and o...Read more -

Industrial X52Q seamless steel pipe strength

As a common pipe material, steel pipes are widely used in all walks of life. Among them, X52Q seamless steel pipes are favored for their excellent performance and reliable quality. As one of its most basic performance indicators, the strength of steel pipes is directly related to its safety and s...Read more -

Anti-rust issues of industrial hot-dip galvanized steel pipes

As a common steel product, hot-dip galvanized steel pipe is widely used in many fields such as construction, chemical industry, and machinery. However, steel will inevitably be affected by factors such as oxidation and corrosion during use, thus affecting its performance and service life. First, ...Read more

- Email Support info@hunantube.com

- Call Support +86-0731-88672086