-

Anti-corrosion performance of galvanized steel pipe dn15

Steel pipes play an important role in the construction and engineering fields, and galvanized steel pipe dn15, as one of the common models, has attracted much attention. With the continuous development of engineering construction, the requirements for materials are becoming higher and higher, esp...Read more -

How to clean industrial straight seam steel pipes

The straight seam steel pipe structure can adopt a round pipe structure or a rectangular pipe structure according to specific conditions such as the stress conditions of the components, supply conditions, manufacturing and processing conditions, and cost, or the two types of steel pipes can be mi...Read more -

Analysis of factors affecting the process of high-frequency straight seam welded pipe

The main process parameters of high-frequency straight seam welded pipes include welding heat input, welding pressure, welding speed, opening angle size, the position and size of the induction coil, the position of the resistor, etc. These parameters have a great impact on improving the quality o...Read more -

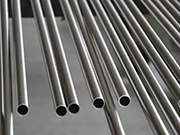

Industrial cold rolled seamless steel pipe 300mm details

Cold-rolled seamless steel pipes, especially models with a diameter of 300mm, occupy an irreplaceable position in modern industry with their high precision and excellent performance. This type of steel pipe has attracted much attention due to its unique production process and wide range of applic...Read more -

Advantages of industrial DN800 steel pipe

Steel pipe is a vital material in modern construction and infrastructure construction. Among them, DN800 steel pipe has attracted much attention and has become the darling of the engineering field because of its unique characteristics. Let’s take a closer look at this remarkable building material...Read more -

Thin-walled galvanized steel pipe is an anti-corrosion tool used in engineering construction

With the continuous development of the construction industry, more and more attention has been paid to the selection of materials. Thin-walled galvanized steel pipes, as an important building material, are widely used in engineering construction. First, the characteristics of thin-walled galvaniz...Read more -

Detail of high-quality alloy steel pipe ASTM5115 steel pipe

ASTM5115 steel pipe, as one of the representatives of high-quality alloy steel pipes, plays an important role in the steel industry. Not only is it widely used in structural engineering, machinery manufacturing, and other fields, but it is also highly favored for its excellent performance. 1. Cha...Read more -

Analysis of the advantageous characteristics and application fields of A335P22 seamless steel pipe

As an important construction and engineering material, steel pipes play an irreplaceable role in all walks of life, and A335P22 seamless steel pipes, as one of them, have attracted much attention. 1. Characteristics of A335P22 seamless steel pipe A335P22 seamless steel pipe is a type of alloy ste...Read more -

Industrial 200 galvanized steel pipe detail

Steel pipe, as one of the indispensable materials in the construction industry, plays an important structural role. Among many steel pipes, 200 galvanized steel pipes are popular for their unique characteristics. 1. Characteristics of 200 galvanized steel pipe 200 galvanized steel pipe refers to ...Read more -

Forged flange production process

The forging process generally consists of the following steps, namely, selecting high-quality steel billets for blanking, heating, forming, and cooling after forging. The forging process methods include free forging, die forging, and membrane forging. During production, different forging methods ...Read more -

What are the characteristics of industrial galvanized steel sheets

1. Strong corrosion resistance The surface of the galvanized steel plate is coated with a layer of zinc. Zinc has strong anti-corrosion properties and can effectively prevent the steel from being oxidized, thereby extending the service life of the steel. In addition, the cathodic protection effec...Read more -

What is the process flow of thickened steel plate rounding processing

When performing rounding processing of thickened steel plates, a series of technological processes are required. The following is a possible process flow for reference: 1. Material preparation: Select a suitable thickened steel plate and ensure that its quality meets the requirements. For the rou...Read more

- Email Support info@hunantube.com

- Call Support +86-0731-88672086