-

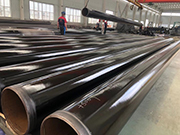

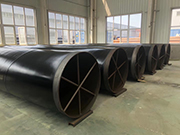

Process, characteristics, and applications of DN600 large diameter anti-corrosion spiral steel pipe

In today’s industrial field, DN600 large-diameter anti-corrosion spiral steel pipe is an important pipeline material and is widely used in petroleum, chemical industry, water treatment, and other fields. First, the manufacturing process of DN600 large-diameter anti-corrosion spiral steel pi...Read more -

Advantages and application value of DN25 galvanized steel pipe

Galvanized steel pipes play an important role in the industrial field, and DN25 galvanized steel pipes have attracted even more attention. 1. Basic introduction to DN25 galvanized steel pipe DN25 galvanized steel pipe refers to a steel pipe with a diameter of DN25 that has been galvanized. This k...Read more -

What precautions should be taken during the processing of steel pipes

During the processing of steel pipes, some important precautions need to be followed to ensure quality and safety. First of all, operators need to undergo professional training and be familiar with equipment operating procedures before they can start working. This is because steel pipe processing...Read more -

What are the treatment methods for stainless steel pipes

There are many ways to treat stainless steel pipes, including the following: 1. Mirror treatment: Polishing the outer layer of stainless steel can be divided into two methods: physical and chemical. This method can make stainless steel more concise, high-end, fashionable, and advanced. 2. Sandbla...Read more -

What causes straight seam steel pipes to bend during production

The straightening of straight seam steel pipes is an important process in the production of straight seam steel pipes. Especially for API standard oil casings, oil and gas pipes, and special pipes for mechanical equipment that require higher quality. These steel pipes not only have strict require...Read more -

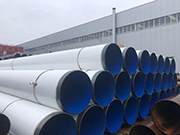

Large diameter flange connection plastic coated steel pipe

The flange connection of plastic-coated steel pipes is to weld the flanges on both ends of the steel pipe first, then shoot blast the inside and outside to remove rust, and then spray epoxy resin powder inside and outside. The plastic-coated steel pipes for water supply are suitable for the worki...Read more -

Detail of internal and external hot-dip galvanized steel pipes

With the rapid development of modern industry and urban construction, steel pipes, as an important building material, have become more and more widely used. Among the many types of steel pipes, internal and external hot-dip galvanized steel pipes have gradually emerged in fields such as construct...Read more -

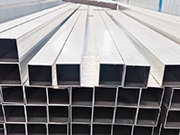

The difference and connection between steel pipe and section steel

First, the details of the steel pipe Is the steel pipe a section of steel? This is a question that bothers many people. In the steel industry, steel pipes and steel sections are two different products, each with unique characteristics and application scenarios. Second, the definition of steel pip...Read more -

Characteristics of fire-fighting plastic-coated steel pipes, differences between galvanized steel pipes and plastic-coated steel pipes

First, the characteristics of fire-fighting plastic-coated steel pipes: 1. It is hygienic, non-toxic, does not accumulate scale, does not breed microorganisms, and ensures fluid quality. 2. It has strong flame retardant ability. Under the combustion test, the coating will not spontaneously ignite...Read more -

How does the hot-rolled steel pipe process affect the quality of steel pipes

The impact of hot-rolled steel pipe technology on steel pipe quality is mainly reflected in the following aspects: 1. Rolling temperature: Rolling temperature is one of the most important parameters in the hot rolling process. If the temperature is too high, the steel may overheat, oxidize, or ev...Read more -

How to maintain steel plates to extend their service life

To extend the service life of steel plates, the following maintenance measures can be taken: 1. Cleaning: Clean the steel plate surface regularly to remove accumulated dust, dirt, and chemicals. You can use mild detergent and a soft cloth for cleaning. Avoid using acidic or corrosive cleaners to ...Read more -

How to improve the corrosion resistance of stainless steel

With the rapid advancement of industrial development, stainless steel, as an important material, has been widely used in many fields, especially in the steel industry. However, stainless steel will still be affected by corrosion under certain conditions, so how to improve the corrosion resistance...Read more

- Email Support info@hunantube.com

- Call Support +86-0731-88672086