-

Installation points of stainless steel elbow

1. Before installation, carefully check the various standards of the stainless steel elbow to see if the diameter meets the usage requirements, eliminate defects caused by the transportation process, and eliminate the dirt on the stainless steel elbow. Make preparations before installation and be...Read more -

Hardness index of anti-corrosion spiral steel pipe

The ability of a metal material to resist surface indentation by hard objects is called hardness depending on the test method and scope of application. Hardness can be divided into Vickers hardness, Shore hardness, Brinell hardness, Rockwell hardness, microhardness, and high-temperature Hardness,...Read more -

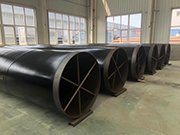

The difference between reinforced 3PE anti-corrosion steel pipes and ordinary 3PE anti-corrosion steel pipes

Currently, there are two standards for 3PE anti-corrosion steel pipes, namely GB/T 23257-2009 and GB/T 23257-2017. GB/T 23257-2017 is a new standard and was implemented in December 2017. The two standards differ mainly in the following aspects: 3PE anti-corrosion steel pipe 1. The design temperat...Read more -

Detailed explanation of spiral steel pipe production process and process characteristics

Spiral steel pipe production process (1) Raw materials include steel strip coil, welding wire, and flux. They must undergo strict physical and chemical inspections before being put into use. (2) The head and tail of the steel strip are butt-jointed using single-wire or double-wire submerged arc w...Read more -

Classification and uses of stainless steel tees

Common pipeline-connecting tools include elbows, flanges, tees, etc. They play the role of connectors in pipelines. Tee is a common connecting element in the pipeline system. There are two production methods: hydraulic bulging and hot pressing. According to the requirements of the use occasion, t...Read more -

Spiral steel pipe connection methods

Generally speaking, the connection method of spiral steel pipes is welding, because welded pipes are relatively low-cost. Some projects will also use other connection methods due to the construction period, construction conditions, geographical environment, and other factors, such as screws. Wen ...Read more -

How does qualified steel pipe behave in terms of straightness, roundness, and welding

1. Straightness: The docking of the straight pipe section of the coiled pipe is a very important part, which requires the accuracy of the coiled pipe cutting, the consistency of the diameter, and the automatic horizontal adjustment of the roller by tools. This can be a good way to find a balance ...Read more -

How to judge the quality of spiral steel pipe

1. From the surface of the spiral steel pipe, you can see whether the production process of the spiral steel pipe is exquisite. Generally, it is necessary to research and analyze spiral steel. The cross-section of fake and inferior spiral steel pipes is oval. The reason is that the manufacturer s...Read more -

Preliminary treatment and use of straight seam steel pipes

Preliminary treatment of straight seam steel pipes: non-destructive testing inside the weld. Since this pipe is an extra-large steel pipe in the water supply project, especially the steel pipe with a thickness of t=30mm is used as a pipe bridge, it must withstand both the internal water pressure ...Read more -

Defects of anti-corrosion of steel pipes coated with epoxy coal pitch paint

1) During on-site construction, the curing of epoxy resin is affected by temperature, the curing is slow, and the construction period is long. 2) Since a large amount of solvent is added during construction, it is easy for some construction units to have the opportunity to cut corners (add more s...Read more -

Advantages of plastic-coated steel pipe as cable protection pipe

Plastic-coated pipes are coated pipes that not only have good corrosion resistance but also have good electrical insulation and low water absorption, extending the service life of the pipes and achieving long-term use. Advantages of plastic-coated steel pipes as cable protection pipes: 1. Suitabl...Read more -

What are the acceptance criteria for steel pipes

① Steel pipe wall thickness inspection: micrometer, ultrasonic thickness gauge, no less than 8 points at both ends and recorded. ② Steel pipe outer diameter and ovality inspection: snap gauge, vernier caliper, ring gauge, measuring point, minimum point. ③Steel pipe length inspection: steel tape m...Read more

- Email Support info@hunantube.com

- Call Support +86-0731-88672086