-

Advantages and disadvantages of carbon steel seamless pipe

Carbon steel seamless pipe (cs smls pipe) is a long steel pipe with hollow section and no joints around it; it is widely used in oil transportation, natural gas, gas, water and the transportation of certain solid materials. Compared with other steel pipes, the cs seamless pipe has a strong advant...Read more -

Seamless Steel Pipe for Ship Building

The seamless steel pipe for ship building usage are mainly used for Level 1& Level 2 pressure pipe in piping system, boiler and super-heated unit of shipbuilding. Model N0.of major steel tubes: 320,360,410,460,490,etc. Sizes: Types of steel tubes Out diameter Wa...Read more -

Performance advantages of seamless pipe

Seamless pipe (SMLS) is a steel pipe made of a single piece of metal with no joints on the surface. It is made of a steel ingot or a solid tube blank through perforation to form a capillary tube, and then hot-rolled, cold-rolled or cold-drawn. The characteristics of seamless steel pipes are diffe...Read more -

ASTM A53 B ERW Steel Pipe

ASTM A53 B ERW Steel Pipe Application 1 Architecture: maximum pipeline under more groundwater extraction when towers, boilers, hot water conveyance and so on. 2 Machining, bearing sets, processing machinery and other accessories. 3 Electrical class: gas distribution, water power fluid conduit. 4 ...Read more -

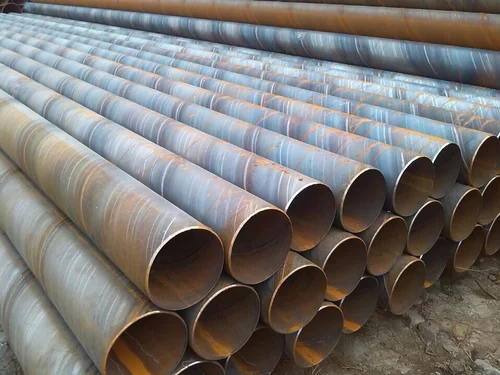

Application field of spiral steel pipe for sewage discharge

Spiral pipe is made by rolling low-carbon carbon structural steel or low alloy structural steel strip into a tube blank according to a certain helical angle (called forming angle), and then welding the pipe seam. It can be made with a narrower strip Steel produces large diameter steel pipes. Its ...Read more -

Factors affecting the yield strength of seamless pipe

Yield strength is an important concept in the field of seamless pipe mechanics. It is the stress value of seamless steel pipe when the ductile material yields. When the seamless steel pipe will deform under the action of force, the deformation at this time can be divided into two ways: plastic de...Read more -

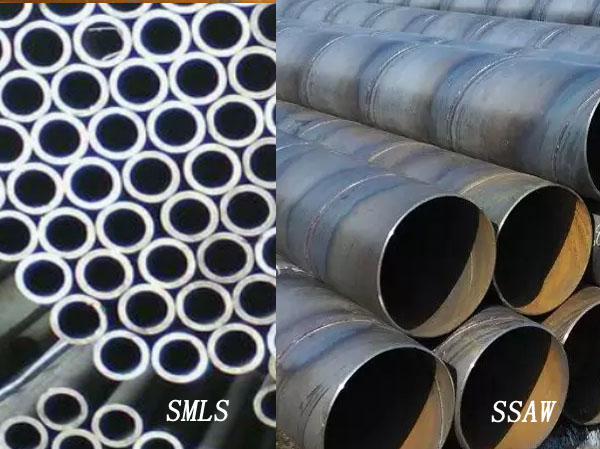

Differences between spiral steel pipe and seamless steel pipe

Spiral steel pipes and seamless steel pipes are relatively common pipes in life, and they are used in house decoration and construction. So what is the difference between spiral steel pipes and seamless steel pipes? What is a spiral steel pipe? Spiral steel pipe (SSAW) is a spiral seam steel pi...Read more -

Precautions for storage and transportation of large diameter spiral welded pipe

What are the precautions for storage and transportation of large-diameter spiral welded pipes? The following editor will introduce it to you. 1. Pipe packaging should be able to avoid loosening and damage during normal loading, unloading, transportation and storage. 2. If the buyer has spe...Read more -

Role of Welding Preheating

Preheating means a process that heat weldments in whole or in weld areas before welding. Particularly good material for welding high strength level, hardening tendency of steel, thermal conductivity, thickness larger weldments, and when the ambient temperature is too low,welding zone often requir...Read more -

Manufacture and application of seamless steel tube

Seamless tubes are tubes without seams or welds. Seamless steel tubes are considered to be able to withstand higher pressures, higher temperatures, higher mechanical stress and corrosive atmospheres. 1. Manufacturing Seamless steel tubes are manufactured using a number of different methods. The m...Read more -

The importance and advantages of anti-corrosion steel pipe

Anti-corrosion steel pipes play important and different roles in people’s daily life. Anti-corrosion steel pipes generally refer to the use of special processes to carry out anti-corrosion treatment on ordinary steel pipes (such as seamless pipes, welded pipes), so that the steel pipes have...Read more -

ERW pipe standard

ERW pipe standard are as follows: API 5L, ASTM A53 B, ASTM A178, ASTM A500/501, ASTM A691, ASTM A252, ASTM A672 API 5L Standard aims to gas and water in oil and gas industry for reference, which is used for seamless steel pipe and welded steel pipe,including common port and port, pipe socket port...Read more

- Email Support info@hunantube.com

- Call Support +86-0731-88672086