-

Introduction to pre-welding and welding essentials of straight seam steel pipes

First, pre-welding of straight seam steel pipes: pre-welding includes joints and welds. 1. The joint (also known as the forming seam) has no misalignment or the misalignment is less than the specified value. Generally, the misalignment is ≤8% of the plate thickness, and the maximum is no more tha...Read more -

The industrial forging flange production process

The forging process generally consists of the following steps, namely, selecting high-quality steel billets for blanking, heating, forming, and cooling after forging. The forging process methods include free forging, die forging, and membrane forging. During production, different forging methods ...Read more -

How to detect the corrosion performance of flanges

The use of flanges in industrial structural parts is mainly to improve the connection function and keep the pipeline sealed without leakage. However, many flanges will corrode and age after a period of use, thus losing the sealing effect, so it is very necessary to perform anti-corrosion tests on...Read more -

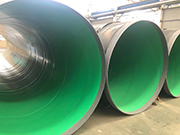

Several common anti-corrosion processes for industrial spiral steel pipes

Anti-corrosion spiral steel pipes play an important and different role in people’s daily lives. Anti-corrosion spiral steel pipes generally refer to the use of special technology to treat ordinary spiral steel pipes that have been treated with anti-corrosion, so that the spiral steel pipes ...Read more -

Quality defects of seamless steel pipe rolling and their prevention

The rolling process is the main process to determine the wall thickness of seamless steel pipes, and its function is to reduce the wall of perforated rough pipes. The main defects are: uneven wall thickness of rough pipes, surface cracks, pits, abrasions, rolling folds, punctures (breaks), etc. 1...Read more -

Galvanized steel pipe is a widely used corrosion-resistant material

Galvanized steel pipe is a common steel product widely used in construction, manufacturing, and industrial fields. It provides excellent corrosion resistance and mechanical strength by coating a layer of zinc on the surface of the steel pipe, so it is very popular. First, the characteristics of g...Read more -

How to choose the appropriate the industrial 120 steel pipe wall thickness

As an important building material, steel pipes are widely used in all walks of life. When purchasing steel pipes, different application scenarios have different requirements for the wall thickness of steel pipes. Among them, the wall thickness of 120 steel pipes is a common parameter. First, the ...Read more -

Understand the characteristics and application areas of common Q45 steel pipes

Q45 steel pipe is a high-quality steel widely used in industrial fields. It has unique characteristics and a wide range of applications. 1. Characteristics of Q45 steel pipe Q45 steel pipe is famous for its excellent mechanical properties and wear resistance, and has the following notable feature...Read more -

What specifications should be used for industrial galvanized steel pipes

With the development of the construction, engineering, and manufacturing industries, galvanized steel pipes have been widely used as an important building material. It has the advantages of corrosion resistance, wear resistance, beauty, and practicality, and plays an important role in protecting ...Read more -

What is the outer diameter of a steel pipe with an inner diameter of 130 commonly used in industrial projects

Steel pipe is a tubular material widely used in construction, manufacturing, and industrial fields. Steel pipe has the characteristics of high strength, corrosion resistance, and good pressure resistance, so it plays an important role in all walks of life. The inner diameter and outer diameter ar...Read more -

Performance characteristics, application fields, and maintenance methods of 2.5-inch galvanized steel pipes

In modern construction, engineering, and manufacturing, steel products are one of the indispensable materials. Among them, galvanized steel pipes are favored for their excellent anti-corrosion performance and wide application fields. As a common specification, the performance characteristics, app...Read more -

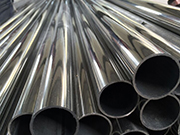

About what grade of steel pipe is 316 stainless steel pipe

In the steel industry, 316 is a stainless steel pipe belonging to the austenitic stainless steel series. It is widely used in various industrial fields, such as petroleum, chemical industry, food processing, pharmaceutical industry, etc., because of its good corrosion resistance and high-temperat...Read more

- Email Support info@hunantube.com

- Call Support +86-0731-88672086