-

Precision Tube length Measurement Method

According to the technological requirements of different manufacturers, precision tubes length measurement systems with a variety of length measurement methods. There are the following: 1, The grating length measurement The basic principle is: the outer ends of precision tubes are provided two fi...Read more -

ERW oil casing application and market analysis

In the field of oil drilling and oil well, high-frequency electric resistance welded casing (referred to as ERW casing) compared with seamless casing is high dimensional accuracy, weld toughness, anti-extrusion of high-performance, and low cost advantages, which has been widely used in foreign co...Read more -

Large-diameter LSAW Steel Pipe Production Process

Large-diameter LSAW steel pipe production process mainly explained: 1. plate probe: used to manufacture large diameter submerged arc welded steel pipe joints straight after entering the production line, the first full-board ultrasonic testing; 2. Milling: Milling machine through the two-sided edg...Read more -

Tube Billet Heating Defects and Its Prevention

Hot-rolled seamless steel pipe from the tube to the product generally requires two heating, which perforated tube before and after heating and rolling blank pipe diameter at a given pre-heating; production of cold-rolled (pull) when the pipe requires the use of an intermediate annealing to elimin...Read more -

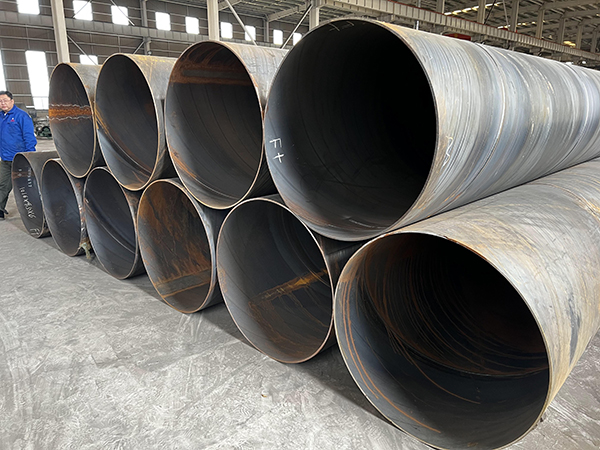

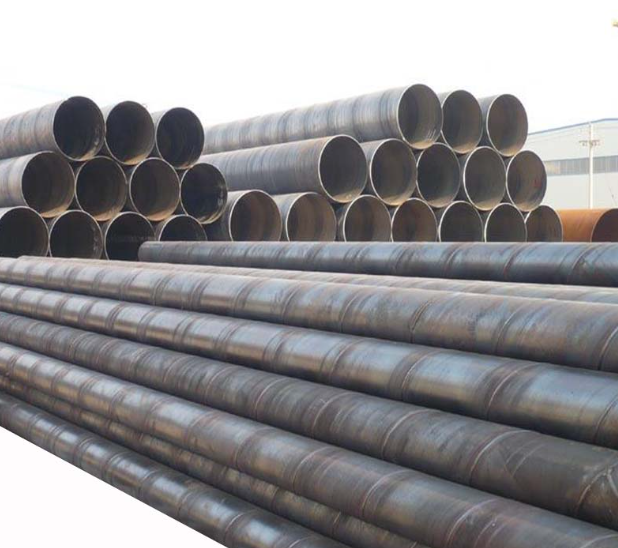

Spiral Weld Seam

Spiral weld seam has the following several types: 1. Spiral strip end weld: steel head that spiral weld on steel or steel weld head and tail; 2. Two spiral butt weld: spiral cut is to link the two together to form an annular weld; 3. Spiral tack welding: that is applied before the final welding. ...Read more -

Production of Cold Drawing Petroleum Cracking Tube

Production of cold drawing petroleum cracking tube can be cold-rolled, cold drawn, cold-drawn, cold-mix production. Using drawing process, a simple equipment, low investment, easy operation and maintenance and so on. But the drawback is the middle step of many, lumber rate. Using cold process equ...Read more -

Cause of the Welds in Trachoma

Spiral Pipe(ssaw steel pipe): by strip by roll forming machine, folding spiral direction, and then double-sided submerged arc welding is made through a capacitor. Spiral welded steel pipe production process, prone to leakage in many cases, such as welding and the wrong side. However, in these cas...Read more -

Advantages of Galvanized Pipes

Advantages of galvanized pipes is following below: Firstly, galvanized pipe after being hot dip galvanized surface can be protected, and inside the cavity of the pipe or any other coating the corner is difficult to enter, deepen the zinc can easily cover to the top, make whole galvanized pipe can...Read more -

Fire pipeline

Fire pipeline is the pipeline system in order to build a fire, due to the special needs of the fire pipe thickness and material have special requirements, and sprayed red paint, conveying fire water. Fire pipeline means for fire safety, fire-fighting equipment is connected, equipment, transport f...Read more -

HSAW pipes

HSAW pipes (spiral submerged arc welded pipe),is mabe of hot-rolled strip steel and bending formed according to spiral, automatic submerged arc welding carried out within the seam and the outer seam welded spiral seam steel pipe (also known as spiral welded pipe, spiral pipe, spiral steel pipe). ...Read more -

Mild carbon steel pipe

Mild carbon steel pipe is one of boilr pipes used in the the power plant boiler pipe. Most of these tubes work under high temperature and pressure, therefore, there is certain requirements on the mechanical properties of mild carbon steel pipe, welding performance and organizational performance, ...Read more -

Quenching technology of straight seam welded pipe

Straight seam welded pipe surface quenching and tempering heat treatment is usually carried out by induction heating or flame heating. The main technical parameters are surface hardness, local hardness and effective hardened layer depth. Hardness testing can use Vickers hardness tester, Rockwell ...Read more

- Email Support info@hunantube.com

- Call Support +86-0731-88672086