-

Control of 304 Stainless Steel Thick-walled Tube Grain Size

304 stainless steel thick-walled tube parts to control grain size during heat treatment is necessary, its quality heat-treated 304 stainless steel thick-walled tube has a very important impact. Here’s how to control the size of its grain size Method Summary as follows. (1) Choose a reasonab...Read more -

304 Stainless Steel Seamless Pipe Wear

304 stainless steel seamless pipe wear phenomenon is very common, many reasons for this phenomenon have physico-chemical and mechanical aspects, mainly by the abrasive wear, adhesive wear (glued), fatigue wear (pitting) corrosion and wear. 304 stainless steel seamless pipe and wear almost all pro...Read more -

How to Weld for Large-diameter Welded Steel Pipe at Low Temperatures

Under cold conditions a low-carbon steel welding, the cooling rate of the welded joint, which has made cracking tendency to increase, especially in the first weld Heavy structures susceptible to cracking, it is necessary to take the following process steps: 1) Do not possible under conditions of ...Read more -

Derusting Work Process of Thick Wall Straight Seam Welded Pipe

To walled Longitudinal rust oil treatment, we must first understand the characteristics and type of anti-rust oil, as well as their respective roles. So when buying such products can not be thrown off balance, indirectly save time. 1. Quick-drying Its biggest advantage is that dry fast, hard shel...Read more -

Microstructure and Properties of Hot-rolled Seamless Steel Pipe

At present, domestic steel producers face enormous challenges seamless steel overcapacity, have to adjust product structure, eliminate backward production capacity and research and development of high-quality products. Experimental studies have shown: the implementation of control of the cooling ...Read more -

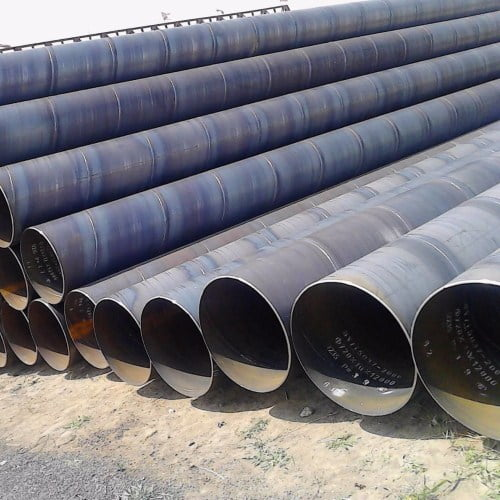

Passivation Process of Spiral Pipe

Since the thicker parts formed on the surface, dense and complex components of the scale, such parts pickling descaling relatively complicated. Such removal of loose oxide scale according to a pickling step of removing ash hung performed. 1, Loose scale: 2, Pickling operation: after loose scale, ...Read more -

Straight Seam Steel Pipe Processing Methods

1. Steel casting: Use forging hammer the reciprocating impact force or press pressure to the billet into a pressure change we desired shape and dimensions plus work approach. 2. Kneading: the steel metal placed in closed kneading Jane, applying pressure at one end of the metal is extruded from th...Read more -

The Advantages of Spiral Pipe for Mining

The advantages of spiral pipe for mining are following below: 1, Closed strong, stiffness. 2, Good corrosion resistance and long service life. 3, Spiral bite from the rib effect, thereby improving the strength of the tube wall thickness can be reduced, reducing the cost of installation works. 4, ...Read more -

Cold Drawn Technology of Spiral Steel Pipe

Spiral steel pipe cold drawn, hot rolled tube defects, such as cracks or spiral steel high-precision cold drawn pipe after the tank, in the course of the fracture, almost no plastic deformation occurs, it is brittle fracture. Brittle fracture is caused by a variety of reasons. Such as: the precip...Read more -

There are spiral steel annealing process in use, mainly in the following three ways

1, To stress annealing Stress relief annealing, also known as low-temperature annealing (or tempering), which is mainly used to eliminate annealing casting, forging, welding, hot-rolled, cold-drawn pieces residual stress and the like. If not eliminate these stresses will cause the steel after a c...Read more -

Surface Treatment of Precision Steel Pipe

Surface treatment of precision steel pipe is by changing the precision steel surface tissue heat treatment to alter one surface properties. Surface hardening eleven surface structure change, without changing the chemical composition of the surface heat treatment. It can be used high-frequency, in...Read more -

Defects of Welded Steel Pipe

Welded steel pipe production process is a steel sheet, strip, and other various molding methods using the straight press roll or helical direction curling into a desired cross-sectional shape, and then by means of heat, pressure, different methods of welding weld together to obtain steel. Therefo...Read more

- Email Support info@hunantube.com

- Call Support +86-0731-88672086