-

The method and requirements of reinforced large-diameter anti-corrosion plastic-coated steel pipes

The method and requirements of reinforced large-diameter anti-corrosion plastic-coated steel pipes: The anti-corrosion treatment method of reinforced large-diameter anti-corrosion plastic-coated steel pipes is primer-primer-glass cloth-topcoat-topcoat-glass cloth-topcoat-topcoat-topcoat, and the ...Read more -

Common large-diameter 3PE anti-corrosion steel pipe performance and details

As a multifunctional steel pipe material, large-diameter 3PE anti-corrosion steel pipe has many advantages and can meet the needs of various pipelines and building structures. From the perspective of environmental protection to service life, the superiority of 3PE steel pipe is very significant. ...Read more -

Comprehensive understanding of the analysis of 40CrNiMo alloy seamless steel pipe

First, the pain point analysis of 40CrNiMo alloy seamless steel pipe Many friends often encounter these problems when choosing 40CrNiMo alloy seamless steel pipe: - Material selection confusion: It is not clear which specific scenarios this material is suitable for - Processing difficulties: The ...Read more -

ASTM A53 welded steel pipe with epoxy coal inner coating

In the field of steel pipe engineering, ASTM A53 welded steel pipe has become the preferred material for many engineering projects with its diverse anti-corrosion treatment and reliable performance, and is widely used in various fluid transportation scenarios. ASTM A53 is a standard for welded an...Read more -

Characteristics and production application details of commonly used industrial Q420MD straight seam welded steel pipe

Q420MD straight seam welded steel pipe is a high-strength low-alloy structural steel welded steel pipe, which is widely used in oil, natural gas, chemical industry, electric power, construction, bridges, and other fields. This steel pipe has become an indispensable and important material in moder...Read more -

Why ordinary three-layer PE anti-corrosion steel pipes are developing rapidly in the steel pipe field

(1) 3PE coating anti-corrosion technology is used in many major steel pipe laying projects. The products of this project comply with the national energy-saving policy. 3PE anti-corrosion steel pipes have increased the service life of the original steel pipes by more than 1 time due to the 3PE ant...Read more -

Processing details of S31254 stainless steel straight seam welded steel pipes commonly used in industrial projects

S31254 stainless steel pipe is a hollow long round steel, which is widely used in industrial pipelines such as petroleum, chemical, medical, food, light industry, mechanical instruments, and mechanical structural components. In addition, when the bending and torsional strengths are the same, the ...Read more -

Performance and production details of alloy steel pipes of 12Cr5MoI seamless steel pipes for petroleum cracking commonly used in industry

With the rapid development of the petroleum industry, the demand for high temperature-resistant and corrosion-resistant seamless steel pipes for petroleum cracking is growing. Among them, 12Cr5MoI seamless alloy steel pipes for petroleum cracking have become popular products on the market with th...Read more -

Common industrial details of Q460C straight seam welded steel pipe

Q460C straight seam welded steel pipe is a high-strength low-alloy structural steel welded steel pipe. With its excellent mechanical properties and welding performance, it is widely used in bridge construction, engineering machinery, high-pressure vessels, and other fields. The following is a det...Read more -

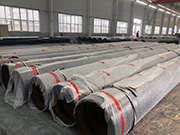

Details of large-diameter hot-rolled seamless steel pipes commonly used in industrial projects

Hello everyone, today we are going to talk about large-diameter hot-rolled seamless steel pipes, especially those “big guys” with a diameter of 219 or above. 1. Related pain points of large-diameter hot-rolled seamless steel pipes: When it comes to these large-diameter steel pipes, th...Read more -

Commonly used seamless steel pipe anti-corrosion details in industrial projects

Seamless steel pipe anti-corrosion: ensure high quality and corrosion resistance. Seamless steel pipes are increasingly used in the storage, processing, and transportation systems of various corrosive media, and the requirements for corrosion resistance are getting higher and higher. How to impro...Read more -

06Cr17Ni12Mo2Ti stainless steel seamless pipe has excellent performance and is an ideal choice for many fields

In the large family of stainless steel materials, 06Cr17Ni12Mo2Ti stainless steel seamless pipe has attracted much attention for its unique performance and wide application. From the perspective of chemical composition, it contains a variety of elements such as carbon ≤0.08%, silicon ≤1.00%, mang...Read more

- Email Support info@hunantube.com

- Call Support +86-0731-88672086