-

Steel elbow process flow

Seamless steel elbow: Steel elbow is a kind of pipe fitting used at the end of the pipeline. Among all the pipe fittings used in the pipeline system, the proportion is about 80%. Usually, different forming processes are selected for steel elbows of different materials or wall thicknesses. Commonl...Read more -

What are the characteristics of the Cr2 steel pipe heat treatment process

The heat treatment process of the Cr2 steel pipe mainly includes steps such as annealing, normalizing, and quenching. These steps have their unique characteristics and purposes. Annealing is to heat the Cr2 steel pipe to about 800°C, hold it for a certain period, and then slowly cool it. The main...Read more -

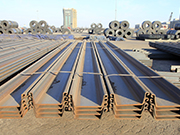

Steel sheet pile construction process

1. Inspection and correction of steel sheet piles Steel sheet piles used for temporary support of foundation pits are inspected for surface defects, length, width, thickness, height, end rectangularity ratio, straightness, and lock shape, and welding parts on the piles that affect the installatio...Read more -

Industrial X52Q seamless steel pipe strength

As a common pipe material, steel pipes are widely used in all walks of life. Among them, X52Q seamless steel pipes are favored for their excellent performance and reliable quality. As one of its most basic performance indicators, the strength of steel pipes is directly related to its safety and s...Read more -

Anti-corrosion performance of galvanized steel pipe dn15

Steel pipes play an important role in the construction and engineering fields, and galvanized steel pipe dn15, as one of the common models, has attracted much attention. With the continuous development of engineering construction, the requirements for materials are becoming higher and higher, esp...Read more -

How to clean industrial straight seam steel pipes

The straight seam steel pipe structure can adopt a round pipe structure or a rectangular pipe structure according to specific conditions such as the stress conditions of the components, supply conditions, manufacturing and processing conditions, and cost, or the two types of steel pipes can be mi...Read more -

Industrial cold rolled seamless steel pipe 300mm details

Cold-rolled seamless steel pipes, especially models with a diameter of 300mm, occupy an irreplaceable position in modern industry with their high precision and excellent performance. This type of steel pipe has attracted much attention due to its unique production process and wide range of applic...Read more -

Advantages of industrial DN800 steel pipe

Steel pipe is a vital material in modern construction and infrastructure construction. Among them, DN800 steel pipe has attracted much attention and has become the darling of the engineering field because of its unique characteristics. Let’s take a closer look at this remarkable building material...Read more -

Thin-walled galvanized steel pipe is an anti-corrosion tool used in engineering construction

With the continuous development of the construction industry, more and more attention has been paid to the selection of materials. Thin-walled galvanized steel pipes, as an important building material, are widely used in engineering construction. First, the characteristics of thin-walled galvaniz...Read more -

Detail of high-quality alloy steel pipe ASTM5115 steel pipe

ASTM5115 steel pipe, as one of the representatives of high-quality alloy steel pipes, plays an important role in the steel industry. Not only is it widely used in structural engineering, machinery manufacturing, and other fields, but it is also highly favored for its excellent performance. 1. Cha...Read more -

Analysis of the advantageous characteristics and application fields of A335P22 seamless steel pipe

As an important construction and engineering material, steel pipes play an irreplaceable role in all walks of life, and A335P22 seamless steel pipes, as one of them, have attracted much attention. 1. Characteristics of A335P22 seamless steel pipe A335P22 seamless steel pipe is a type of alloy ste...Read more -

Industrial 200 galvanized steel pipe detail

Steel pipe, as one of the indispensable materials in the construction industry, plays an important structural role. Among many steel pipes, 200 galvanized steel pipes are popular for their unique characteristics. 1. Characteristics of 200 galvanized steel pipe 200 galvanized steel pipe refers to ...Read more

- Email Support info@hunantube.com

- Call Support +86-0731-88672086