Nickel Alloy Tube

Introduction of Nickel Alloy Tube:

Nickel based alloys are very useful materials for the manufacture of high quality tubing products. One of the key reasons is that they offer excellent corrosion resistance in both aqueous and high temperature applications.In addition to their high melting points and resistance to oxidation and corrosion, nickel alloys are very ductile. They can be electroplated and are easily welded, making them suitable for use in industries where very high and low temperatures come into play.

Nickel based alloys have a higher ability to accept alloying elements in solid solution than other stainless steel or iron-based alloys. They cantherefore maintain higher metallurgical stability. The combination of high alloying with multiple elements can provide very good corrosion resistance in a wide range of environments while still maintaining good welding and forming characteristics.

Feature of Nickel Alloy Tube:

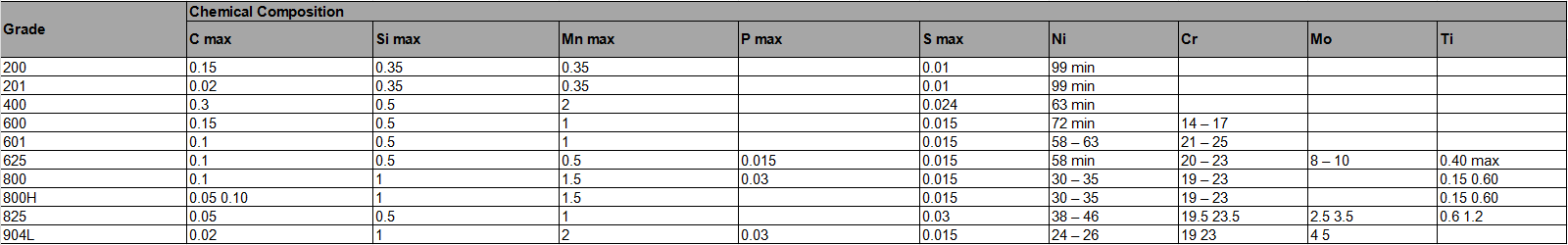

Chemical composition:

Nickel Alloy Physical Properties:

| ALLOY | NICKEL ALLOY DENSITY | THERMAL , CONDUCTIVITY | THERMAL LINEAR , EXPANSION COEFF , (20-95 °C) | ELECTRICAL RESISTIVITY , AT 20°C |

| G/CM³ | W/M K | 10-6/K | ΜΩ-CM | |

| NI 200/201 | 8.89 | 70.2 | 13.3 | 9 |

| NI 205/205 LC | 8.89 | 75 | 13.3 | 8.9 |

Standards of Nickel Alloy Tube:

| Trade Name | UNS # | Seamless Tube | Welded Tube |

| Alloy® 20 | N08020 | B/SB729 | B/SB468 |

| Nickel 200 | N02200 | B/SB161 | B730 |

| B/SB163 | |||

| Nickel 201 | N02201 | B/SB161 | B730 |

| B/SB163 | |||

| Monel® 400 | N04400 | B/SB165 | B730 |

| B/SB163 | |||

| Inconel® 600 | N06600 | B/SB167 | B/SB516 |

| B/SB163 | |||

| Inconel® 625 | N06625 | B/SB444 | B/SB704 |

| Incoloy® 800 | N08800 | B/SB407 | B/SB515 |

| B/SB163 | |||

| A/SA213 | |||

| Incoloy® 800H | N08810 | B/SB407 | B/SB515 |

| B/SB163 | |||

| A/SA213 | |||

| Incoloy® 800HT | N08811 | B/SB407 | B/SB515 |

| B/SB163 | |||

| A/SA213 | |||

| Incoloy® 825 | N08825 | B/SB423 | B/SB704 |

| B/SB163 |

Applications of Nickel Alloy Tube

Nickel alloys are excellent for heat exchangers in the chemical processing and nuclear industries. They’re used in steam generator tubing in the nuclear power industry, in high-temperature aircraft systems, and in oil and gas extraction programmes where corrosion-, pressure- and temperature-resistant tubing is required. Their corrosion resistance also makes them useful in desalination equipment.

Various Uses Of Nickel Alloy Tube:

| Alloy | UNS | Description |

| 200 | N02200 | This alloy provides highly ductile mechanical properties across a wide temperature range. |

| 825 | N08825 | An austenitic nickel-iron-chromium-molybdenum-copper alloy providing high levels of corrosion resistance. |

| 201 | N02201 | This alloy provides highly ductile mechanical properties across a wide temperature range. |

| ALLOY 20 | N08020 | This alloy has excellent resistance to general corrosion, pitting, and crevice corrosion in chemicals containing chlorides and sulfuric, phosphoric, and nitric acids. |

| 400 | N04400 | A ductile nickel-copper alloy with resistance to a variety of corrosive conditions. |

| ALLOY 22 | N06022 | A Ni-Cr-Mo alloy that provides outstanding resistance to pitting, crevice corrosion, intergranular attack, and stress corrosion cracking. |

| 600 | N06600 | Nickel Chromium alloy designed for use from cryogenic to 2000掳F. It is non-magnetic and readily weldable. |

| ALLOY 59 | N06059 | This alloy is a nickel-chromium-molybdenum alloy with an extra-low carbon and silicon content. |

| 601 | N06601 | An austenitic nickel-chromium-iron alloy designed for both heat and corrosion resistance. |

| B-2 | N10665 | This alloy is a solid solution strengthened, nickel-molybdenum alloy, typically used in extreme reducing conditions. |

| 625 | N06625 | An austenitic nickel-base super alloy possessing excellent resistance to oxidation and corrosion over a broad range of corrosive conditions. |

| C276 | N10276 | A nickel-molybdenum-chromium-iron-tungsten alloy which is among the most corrosion resistant of alloys currently available. |

| 686 | N06686 | An alloy designed for outstanding corrosion resistance in a wide range of severe environments. |

| C-2000 | N06200 | An extremely versatile nickel alloy resistant to corrosion in all acids and chloride solutions, over wide temperature ranges. |

| 800 | N08800 | Nickel-iron-chromium alloys designed to resist oxidation and carburization at elevated temperatures. They are highly resistant to chloride stress corrosion cracking and to embrittlement from precipitation of sigma phase. |

| G-3 | N06985 | This alloy has good weldability and resistance to intergranular corrosion in the welded condition. |

| 904L | N08904 | This alloy is designed for a middle to high level of corrosion resistance. |

| 800H | N08810 | Nickel-iron-chromium alloys designed to resist oxidation and carburization at elevated temperatures. They are highly resistant to chloride stress corrosion cracking and to embrittlement from precipitation of sigma phase. |

| G-30 | N06030 | A high chromium nickel-base alloy which shows superior corrosion resistance over most other nickel and iron-base alloys in commercial phosphoric acids and complex environments containing highly oxidizing acids. |

| 800HT | N08811 | Nickel-iron-chromium alloys designed to resist oxidation and carburization at elevated temperatures. They are highly resistant to chloride stress corrosion cracking and to embrittlement from precipitation of sigma phase. |