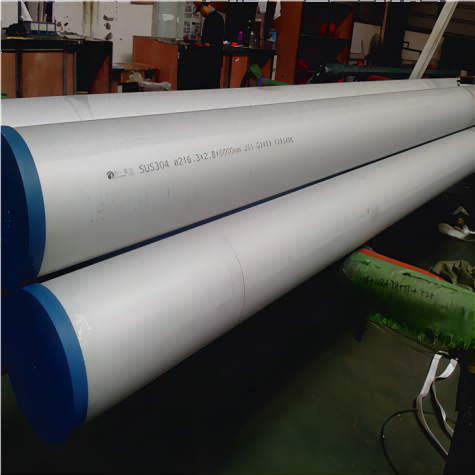

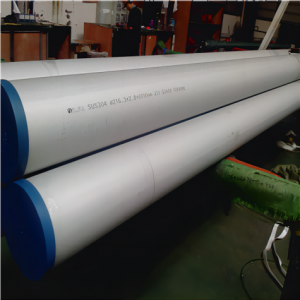

Stainless Steel Pipe For Industrial

Introduction of Stainless steel pipe for industrial fluid transportation:

Stainless steel pipe for industrial fluid transportation is a high temperature and high pressure heat resistant carbon low alloy steel pipe, can be used in thermal equipment, machinery industry, petroleum geological exploration, containers, chemical industry and special purposes. Because the working environment is mostly under the action of high temperature, high pressure and water vapor, oxidation and corrosion are easy to occur, which requires the product to have high durable strength, high oxidation corrosion resistance, and good organizational stability.

Dimensional Tolerance Table For Stainless Steel Pipe For Industrial Fluid Transportation:

| Standard | Outside Diameter ( m m ) | Thickness ( m m ) | Length(mm) | ||||

| ASTM A312 | ≤48.26 | +0.40-0.80 | unspecified -12.50% |

Definite cut length +6.40 -0 |

|||

| >48.26-114.30 | +0.80-0.80 | ||||||

| >114.30-219.08 | +1.60-0.80 | ||||||

| >219.08~457.20 | +2.40-0.80 | ||||||

| >457-660 | +3.20/-0.80 | ||||||

| >660-864 | +4.00/-0.80 | ||||||

| >864~1219 | +4.48/-0.80 | ||||||

| HG 20537.3/4 | Dn≤150 150<DN<300 Dn≥300 |

±0.75%,min±0.3mm ±1% ±1% |

±10%S,min±0.3mm | +6.00 -0 |

|||

| GB/T 12771 | <13.00 13.00-40.00 ≥40.00 |

±0.20 ±0.30 ±0.80% |

≤4.00 >4.00 |

+0.50 -0.60 ±10% |

+20.00 -0 |

||

| EN 10217-7 | D1±1.50% with±0.75mm(min D2±1.00% with±0.50mm(min) D3±1.75% with±0.30mm(min) D4±0.50% with±0.10mm(min) EN ISO 1127 |

T1±15.00% T2±12.5% T3±10.00% T4±7.50% T5±5.00% EN |

with±0.60mm(min) with±0.40mm(min) with±0.20mm(min) with±0.15mm(min) with±0.10mm(min) ISO 1127 |

≤6000 +5.00 -0 6000~12000 +10.00 -0 |

|||

| EN 10217-7 | D1±1.50% with±0.75mm(min D2±1.00% with±0.50mm(min) D3±1.75% with±0.30mm(min) D4±0.50% with±0.10mm(min) EN ISO 1127 |

T1±15.00% T2±12.5% T3±10.00% T4±7.50% T5±5.00% EN |

with±0.60mm(min) with±0.40mm(min) with±0.20mm(min) with±0.15mm(min) with±0.10mm(min) ISO 1127 |

≤6000 +5.00 -0 6000~12000 +10.00 -0 |

|||

ASTM A312/ASTM A778 Specification

| Nominal Diameter | Outside Diameter | Nominal Wall Thickness | |||

| SCH5S | SCH 10S | SCH 40S | |||

| N.B | NPS | mm | mm | mm | mm |

| 8 | 1/4 | 13.72 | 2.24 | ||

| 10 | 3/8″ | 17.15 | 2.31 | ||

| 15 | 1/2* | 21.34 | 1.65 | 2.11 | 2.77 |

| 20 | 3/4″ | 26.67 | 1.65 | 2.11 | 2.87 |

| 25 | 1* | 33.4 | 1.65 | 2.77 | 3.38 |

| 32 | 1-1/4″ | 42.16 | 1.65 | 2.77 | 3.56 |

| 40 | 1-1/2″ | 48.26 | 1.65 | 2.77 | 3.68 |

| 50 | 2* | 60.33 | 1.65 | 2.77 | 3.91 |

| 65 | 2-1/2″ | 73.03 | 2.11 | 3.05 | 5.16 |

| 80 | 3* | 88.90 | 2.11 | 3.05 | 5.49 |

| 90 | 3-1/2″ | 101.60 | 2.11 | 3.05 | 5.74 |

| 100 | 4″ | 114.30 | 2.11 | 3.05 | 6.05 |

| 125 | 5* | 141.30 | 2.77 | 3.4 | 6.55 |

| 150 | 6* | 168.28 | 2.77 | 3.4 | 7.11 |

| 200 | 8* | 219.08 | 2.77 | 3.76 | 8.18 |

| 250 | 10* | 273.05 | 3.40 | 4.19 | 9.27 |

| 300 | 12* | 323.85 | 3.96 | 4.57 | 9.52 |

JIS G3459 Specification

| Nomina Diameter | Outside Diameter | Nominal Wall Thickness | ||||

| SCH5S | SCH 10S | SCH 20S | SCH40S | |||

| (A) | (B) | mm | mm | mm | mm | mm |

| 8 | 1/4″ | 13.8 | 1.2 | 1.65 | 2.0 | 2.2 |

| 10 | 3/8″ | 17.3 | 1.2 | 1.65 | 2.0 | 2.3 |

| 15 | 1/2″ | 21.7 | 1.65 | 2.1 | 2.5 | 2.8 |

| 20 | 3/4″ | 27.2 | 1.65 | 2.1 | 2.5 | 2.9 |

| 25 | 1″ | 34.0 | 1.65 | 2.8 | 3.0 | 3.4 |

| 32 | 1-1/4″ | 42.7 | 1.65 | 2.8 | 3.0 | 3.6 |

| 40 | 1-1/2″ | 48.6 | 1.65 | 2.8 | 3.0 | 3.7 |

| 50 | 2″ | 60.5 | 1.65 | 2.8 | 3.5 | 3.9 |

| 65 | 2-1/2 | 76.3 | 2.1 | 3.0 | 3.5 | 5.2 |

| 80 | 3″ | 89.1 | 2.1 | 3.0 | 4.0 | 5.5 |

| 90 | 3-1/2 | 101.6 | 2.1 | 3.0 | 4.0 | 5.7 |

| 100 | 4″ | 114.3 | 2.1 | 3.0 | 4.0 | 6.0 |

| 125 | 5″ | 139.8 | 2.8 | 3.4 | 5.0 | 6.6 |

| 150 | 6″ | 165.2 | 2.8 | 3.4 | 5.0 | 7.1 |

| 200 | 8″ | 216.3 | 2.8 | 4.0 | 6.5 | 8.2 |

| 250 | 10° | 267.4 | 3.4 | 4.0 | 6.5 | 9.3 |

| 300 | 12 | 318.5 | 4.0 | 4.5 | 6.5 | 10.3 |

Large diameter stainless steel pipe

ASTM A312/ASTM A778 Specification

| Nomina Diameter | Outside Diameter | Nominal Wall Thickness | ||||

| SCH 5S | SCH 10S | SCH 20S | SCH 40S | |||

| (A) | (B) | mm | mm | mm | mm | mm |

| 350 | 14 | 355.6 | 3.96 | 4.78 | 7.92 | 11.13 |

| 400 | 16 | 406.4 | 4.19 | 4.78 | 7.92 | 12.7 |

| 450 | 18 | 457.2 | 4.19 | 4.78 | 7.92 | 14.27 |

| 500 | 20° | 508.0 | 4.78 | 5.54 | 9.53 | 15.09 |

| 550 | 22 | 558.8 | 4.78 | 5.54 | 9.53 | 15.09 |

| 600 | 24 | 609.6 | 5.54 | 6.35 | 9.53 | 17.48 |

| 650 | 26 | 660.4 | 5.54 | 7.92 | 12.7 | 17.48 |

| 700 | 28″ | 711.2 | 5.54 | 7.92 | 12.7 | 17.48 |

| 750 | 30° | 762.0 | 6.35 | 7.92 | 12.7 | 17.48 |

| 800 | 32″ | 812.8 | 7.92 | 12.7 | 17.48 | |

| 850 | 34* | 863.6 | 7.92 | 12.7 | 17.48 | |

| 900 | 36 | 914.4 | 7.92 | 12.7 | 19.05 | |

| 1000 | 40° | 1016.0 | 9.53 | |||

GB12770 Dimension tolerance table

| Category | outside diameter | Allowable deviation | ||

| PC | PR | PA | ||

| T | <13 | ±0.10 | ±0.20 | ±0.25 |

| ≥13~<25 | ±0.13 | ±0.20 | ±0.40 | |

| ≥25~<40 | ±0.25 | ±0.30 | ±0.60 | |

| ≥40~<63 | ±0.30 | ±0.50 | ±0.80 | |

| ≥63-<90 | ±0.51 | ±0.60 | ±1.0 | |

| ≥90-<159 | ±0.64 | ±0.80 | ±1.0 | |

| ≥159~<300 | ±0.7%D | ±0.8%D | ±1.0%D | |

| ≥300~<500 | ±0.8%D | ±1.0%D | ±1.25%D | |

| ≥500 | on agreement | on agreement | on agreement | |

| WSP | <25 | ±0.10 | ±0.12 | ±0.15 |

| ≥25~<40 | ±0.13 | ±0.15 | ±0.18 | |

| ≥40~550 | ±0.15 | ±0.18 | ±0.20 | |

| ≥50-<60 | ±0.18 | ±0.20 | ±0.23 | |

| ≥60~<70 | ±0.25 | ±0.28 | ±0.30 | |

| ≥70-<80 | ±0.25 | ±0.28 | ±0.30 | |

| ≥80-<90 | ±0.25 | ±0.28 | ±0.30 | |

| ≥90~<100 | ±0.30 | ±0.35 | ±0.40 | |

| ≥100~<200 | on agreement | ±0.4%D | ±0.5%D | |

| ≥200 | on agreement | on agreement | on agreement | |

GB12770 Wall thickness tolerances

| Category | Wall thickness | Wall thickness tolerance |

| Cold-rolled steel plate(coil) cold rolled slitting strip | ≤0.5mm | ±0.05mm |

| >0.5~1.0mm | ±0.11mm | |

| >1.0-2.0mm | ±0.17mm | |

| >2.0~3.0mm | +7%mms | |

| ≥3.0~4.0mm | ±6%Smm | |

| >4.0~5.0mm | ±5%Smm |

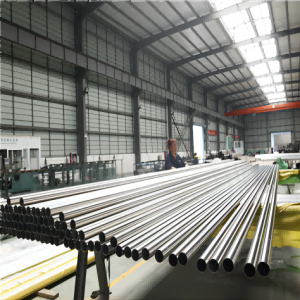

Application of Stainless steel pipe for industrial fluid transportation:

•Pipeline Transport •Boiler Pipe •Hydraulic/Automobile Pipe

•Oil/Gas Drilling

•Food/Beverage/Dairy Products

•Machinery Industry

•Chemical In dustry, Mining

•Construction & Decoration, Special Purpose