Stainless Steel Profile

Introduction of Stainless Steel Profile:

Stainless steel profiles are materials made of stainless steel in various cross-sectional shapes. They are commonly used in construction, manufacturing, and industrial applications as structural components, decorative elements, or other materials for specific purposes.

Stainless steel profiles can be classified into various types according to their cross-sectional shape, including angles, I-beams, channels, rounds, squares, etc. These profiles have the characteristics of stainless steel, such as corrosion resistance, heat resistance, wear resistance, and good strength.

Stainless Steel C-Shaped Steel:

|

Product Name

|

Stainless Steel C-Shaped Steel

|

|||

|

Material

|

201, 202, 301, 302, 304, 304L, 310S, 316, 316L, 321, 430, 430A, 309S, 2205, 2507, 2520, 430 , 410, 440, 904Lect, Or Customized

|

|||

|

Surface

|

BA, 2B, 2D, 4K, 6K, 8K, NO.4, HL, SB, Embossed

|

|||

|

Thinckness

|

0.3mm-60mm

|

|||

|

Widthness

|

50mm~2000mm or customized

|

|||

|

Length

|

1000mm~8000mm or customized

|

|||

Stainless Steel H-Beam / I-Beam:

|

Product name

|

Stainless Steel H-Beam / I-Beam

|

|

Standard

|

JIS, AiSi, ASTM, GB, DIN, EN

|

|

Size

|

100mm-900mm

|

|

Wall thickness

|

1.5mm-28mm

|

|

Material grade

|

301 303 303Cu 304 304J1 304L 316 316L 309S 310S 316Ti 321 430 420 410 409L 904L

|

|

Application

|

Hardware products, medical machinery, food machinery, ships, cars, doors and Windows, furniture, large machinery, etc

|

|

Processing Service

|

Bending, Welding, Decoiling, Punching, Cutting, Moulding

|

|

Keyword

|

Stainless steel profile,stainless steel bar,huel bars,rod,steel rods

|

Stainless Steel Flat Steel:

|

Key word

|

stainless steel flat bar 316

|

|

Material

|

300 Series /400 Series

|

|

Thickness

|

2mm-100mm

|

|

Width

|

10mm-500mm

|

|

Application

|

Industry, Construction

|

|

Surface

|

Pickled,Black,Bright,Polishing,Blasting,etc

|

|

Model Number

|

304,304L,309S,310S,316,316L,316Ti,317,317L,321,347H,201,202,405,409

|

|

Tolerance

|

±1%

|

|

Processing Service

|

Bending, Welding, Decoiling, Punching, Cutting

|

What are the surfaces of stainless steel coils? We mainly introduce the surface of stainless steel coils for industrial use.

The most important ones on the market are NO.1, NO.2D, 2B, BA, HL.

| Name | Processing type | Surface Condition | Remarks |

| No.1 | Hot rolling, heat treatment, pickling | No scale | The method of mechanical descaling (coarse grinding or shot peening), the surface roughness is 0.3~0.6μm. |

| NO.2D | Cold rolling, heat treatment, pickling or descaling | The surface is uniform and matt | Heat treatment and pickling after cold rolling. The matt surface is produced by pickling or descaling. It can be smoothed with a rough roller. The rough surface processing facilitates the retention of lubricant on the surface of the steel plate during deep drawing. This kind of surface is suitable for processing deep-drawn parts, but these parts need to be polished after forming, and the surface roughness is 0.3~0.6μm. |

| 2B | Cold rolling, heat treatment, pickling or descaling, bright processing | Smoother and straighter than 2D surface | On the basis of the 2D surface, the steel plate after heat treatment and descaling is smoothed with a small reduction amount with a polishing roller. It is the most commonly used surface processing. Except for extremely complex deep drawing, it can be used for any purpose. The surface roughness is 0.10~0.25μm. |

| BA | Cold rolled, bright annealing | Smooth, shiny, reflective | After cold rolling, bright annealing is performed in a controlled atmosphere furnace. Generally, dry hydrogen or a mixed atmosphere of dry hydrogen and dry nitrogen is used to prevent oxidation during annealing. It is also a commonly used surface processing for subsequent processing. |

| HL | Cold rolling, pickling, leveling, grinding | Continuously rubbed | Polish the surface with an abrasive material of appropriate size to make the surface continuous. |

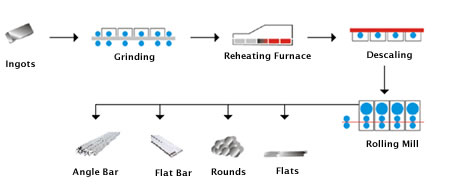

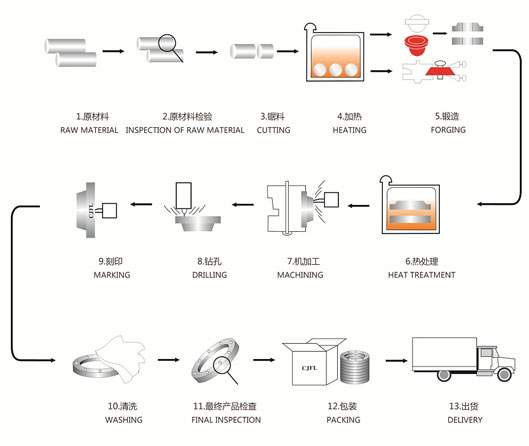

Manufacturing Technique Of Stainless Steel Profile

Application of Stainless Steel Angle

Stainless angle and 304 stainless steel angle products are used for numerous applications throughout a multitude of industries, some of which include:

Aerospace

Architectural

Construction

Chemical

Food Processing

Oil & Gas

And more

Application of H-Beam

- Business Buildings

- Large trailers

- Large bridges

- Industrial plants

- Large large coaxial

- Heavy equipment

- Highway

- Ship skeleton

- Mine support

- Foundation treatment and dam engineering

- Various machine components